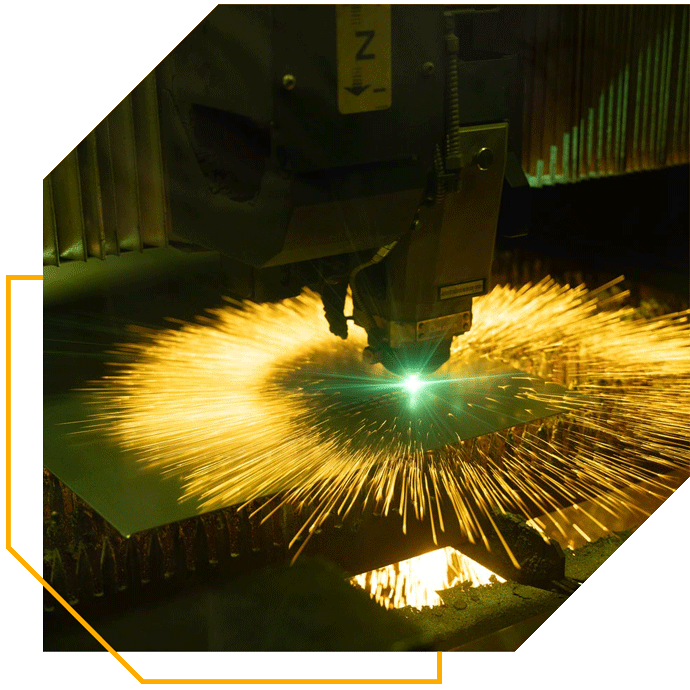

laser cutting

Concept Metal, based excels in laser cutting, an essential process to its services to guarantee unmatched precision. The company serves demanding sectors such as railways, aeronautics and defense. With its expert team and advanced equipment, Concept Metal ensures high-quality production to the highest industrial standards.

what is laser cutting ?

technology description

advantages of laser cutting

Speed & Precision

AMADA fiber laser cutting is distinguished from shearing and punching by its high speed and precision, without direct contact with the material. Where shearing can cause deformation, the laser produces clean, precise cuts, minimizing defects and optimizing the quality of finishes, even on delicate materials.

Completeness & Flexibility

This machine excels in the production of complex, customized shapes, with the ability to cut any geometry from a digital file in DXF format. It thus meets the need for flexibility and precision in a wide variety of projects, offering maximum adaptability.

Diverse applications

Concept Metal laser cutting can be adapted to the needs of a wide range of sectors, including railways, aeronautics and defense. It can be used to produce specific parts such as cable supports for the rail industry, hull components for the aerospace industry or armor components for the defense industry, guaranteeing high quality and performance adapted to each sector.

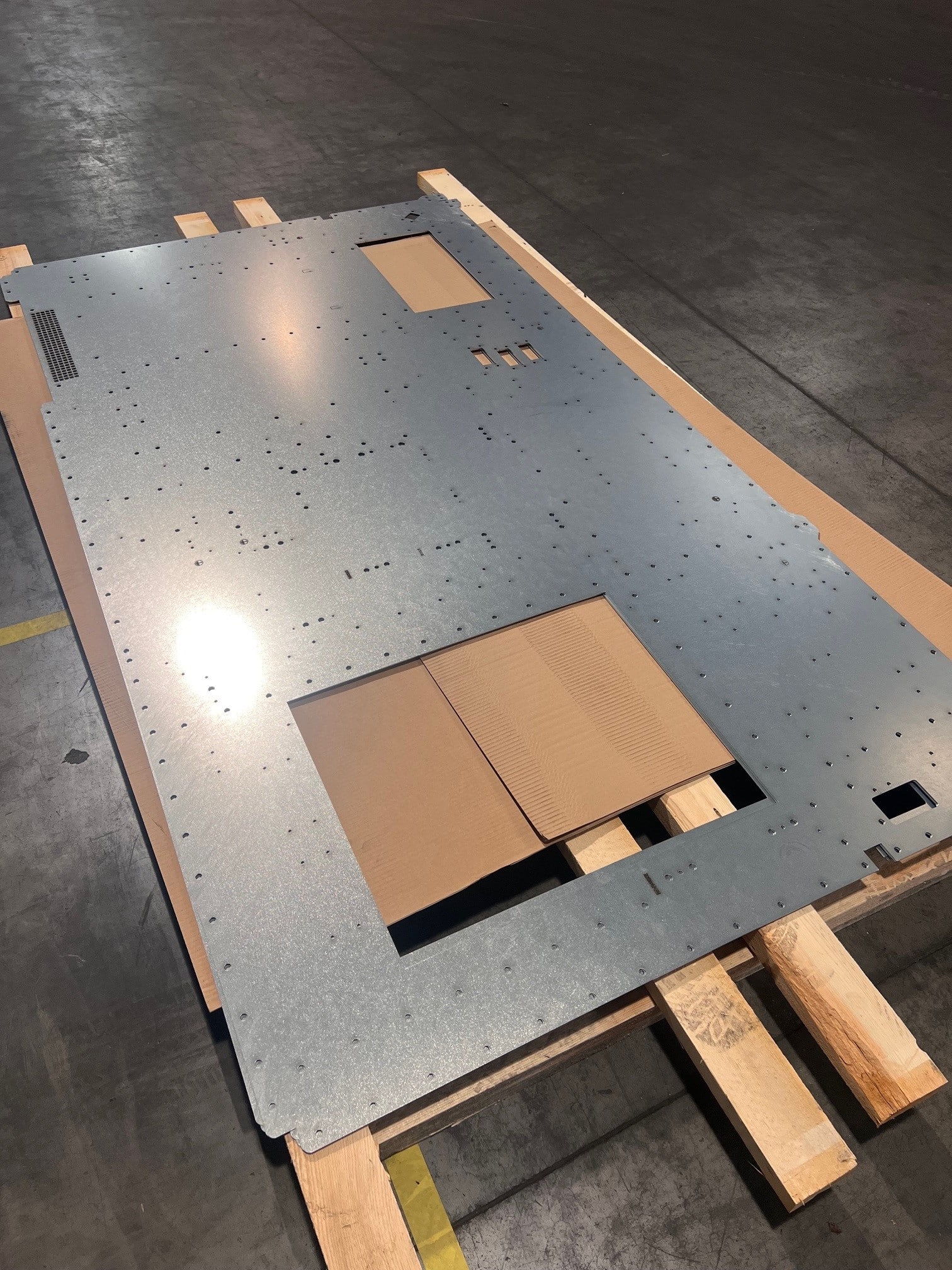

Our achievements

in laser cutting

Concept Metal, specialized in industrial sheet metal work, stands out for its know-how and expertise in the production of high-precision metal parts for large-scale projects. Since its creation, we have met the most stringent requirements of industrial sectors, particularly the railways, by offering customized sheet metal solutions that contribute to the reliability and safety of rolling stock.

For many years, Concept Metal has built its reputation on the production of riveted, screwed and mechanically-welded power cabinets for roofing, train interiors and underframes. These cabinets must comply with the most stringent safety and performance standards.

a question ?

a project ?

Get Your Personalized Quote Today!

Contact us now to receive a custom quote perfectly tailored to your needs. Our responsive and available team supports you throughout your project, providing personalized advice and solutions adapted to your expectations. Don’t waste any more time—we’re here for you!