Metal sheet working specialists

Concept Metal, located in Louey, France, is specialized in the design and manufacture of custom metal structures. Drawing on its expertise and know-how, it offers innovative solutions tailored to the specific needs of its customers, whether private individuals or professionals.

our values

Customer satisfaction

Putting people first

Respect

Commitment to improvement

Certifications

EN 15085-2 CL1

ISO 9001

Over 20

years of experience !

our expertise to serve your projects

Concept Metal puts its expertise in custom-built steel structures at the service of your projects, for reliable, customized solutions.

industrialization

The indusrialiaton department acts as a link between the design office and production to industrialize products, optimizing manufacturing processes from order to delivery, in coordination with the production, quality, procurement and sales teams.

Techniques and equipements

The department is staffed by four technicians and a manager, defines manufacturing processes according to customer specifications, manages manufacturing files, ensures technical liaison with operators and subcontractors, and works with procurement to secure supplies.

Our technicians

Concept Metal uses a number of tools for its production : Clipper, an ERP system for generating parts manufacturing routings; SolidWorks, a 3D CAD/CAE program for analyzing customer models and designing tooling; Production Designer, for creating cutting development and bending programs; and various Microsoft tools for creating production media.

To sum up

The industrialization department is essential to production, and must be rigorous to guarantee the smooth running of operations, from order to delivery. It works with the workshop to improve productivity and quality, while interacting with customers to provide technical solutions and ensure that the final product meets their expectations.

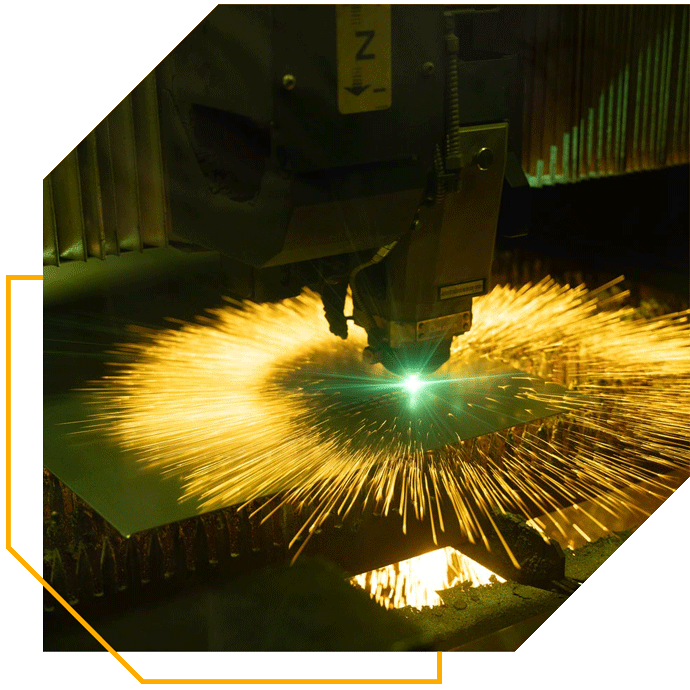

laser cutting

The AMADA fiber laser cutting machine is an advanced solution for industry, capable of cutting various materials such as aluminum, steel, stainless steel, copper and brass. It combines precision and performance, enabling the processing of sheet metal of large dimensions and varied thicknesses for quality results.

Technology description

⚙️Material versatility: Capable of cutting a wide range of materials including aluminum, steel, stainless steel, copper and brass.

⚙️Dimensions and thicknesses: Handles large sheet sizes with maximum thicknesses adapted to production needs.

benefits

Speed & precision

Complexity & Flexibility

Various applications

To sum up

The AMADA fiber laser cutting machine is a high-performance industrial solution, capable of cutting various materials (aluminum, steel, stainless steel, copper, brass) with precision. It processes sheet metal of large dimensions and varied thicknesses, guaranteeing top-quality results.

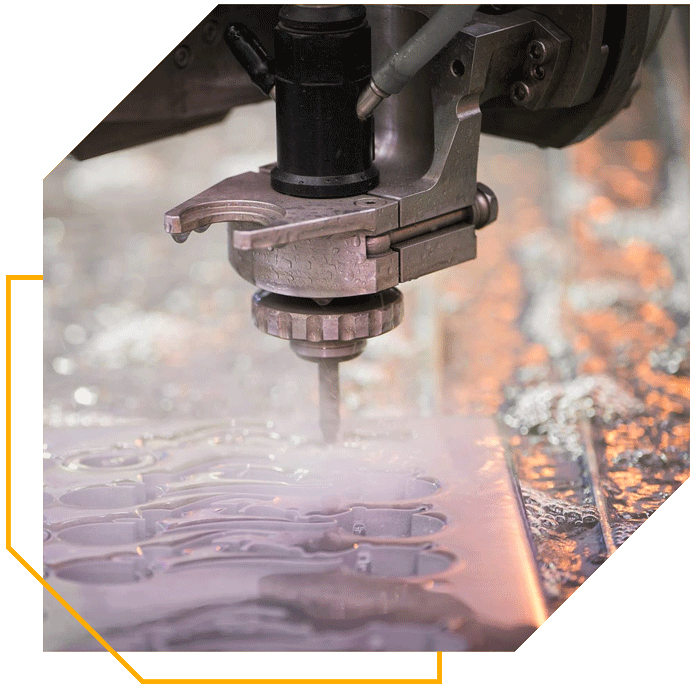

waterjet cutting

The waterjet cutting machine is designed to cut thick materials with great precision and few heat-affected zones. It can cut steel, stainless steel and aluminum from 25 mm thickness, and copper and brass from 12 mm. It is also suitable for a variety of other materials, such as glass, foam, plastic, rubber and ceramics.

Description

🔑 STM Premium Cut waterjet cutting machine with draft compensation

🔑 Acquisition in 2020.

🔑 Dimensions: 4000X2000 mm.

BENEFITS

Material versatility

High cutting capacity

Precision and safety

TO SUM UP

The waterjet cutting machine enables precise cutting of thick materials, up to 25 mm for steel and aluminum, and 12 mm for copper and brass. It is also compatible with various materials such as glass and plastic. It’s an efficient solution for a wide range of industrial applications.

BENDING

Bending transforms flat sheet metal into a permanent shape using press brakes equipped with punch and die. Concept Métal uses the V-bending method to create a variety of parts efficiently. Successful bending depends on the malleability of the metal, the thickness of the sheet, and the length and direction of the bend.

Description

🧷Explanation of bending in metallurgy and its role in sheet metal and wardrare.

🧷The importance of precision and repeatability when bending metal parts.

AMANDA PRESS BRAKES

🧷 Description of three AMADA press brakers:

-

NC 8-axis press brake lg 3000, capacity 100 Tons.

-

NC press brake 8 axes lg 4000, capacity 170 Tons.

-

NC press brake 8 axes lg 3000, capacity 100 Tons with automated tool magazine.

Avantages du pliage

🧷Precision and efficiency

- Press brakes for mass production of parts with precise angles.

- Interface with CAD/CAM software, eliminating the need for manual programming by the operator.

- Possibility of producing crocked parts.

- Flexibility and speed of production thanks to automated press brakes.

- Bending of parts up to 4 meters long.

MECHANICAL WELDING

Concept Métal specializes in customized industrial sheet metal work and the assembly of mechanically welded assemblies. The company uses welding methods (TIG, MIG, MAG) on materials such as stainless steel, steel and aluminum, with welds carried out by qualified welders. Certified to EN 15085, Concept Métal ensures a high level of quality, particularly for the railway sector.

Description

💡Mechanical welding is a specific technique used to design structures with complex shapes and generally large dimensions. It is often combined with other metalworking processes such as cutting, bending, machining, crimping…

💡A mechanically welded assembly is an assembly of metal parts welded together.

Méthodes de soudage utilisées

💡TIG

💡MIG

💡MAG

QUALITY MANAGEMENT

💡Strict product monitoring and control process.

💡Self-control by the operator.

💡Visual control by inspectors.

💡Surface inspection by dye penetrant testing – COFREND PT2 (level 2 dye penetrant testing).

💡Subcontracting for magnetic particle inspection if requested by the customer.

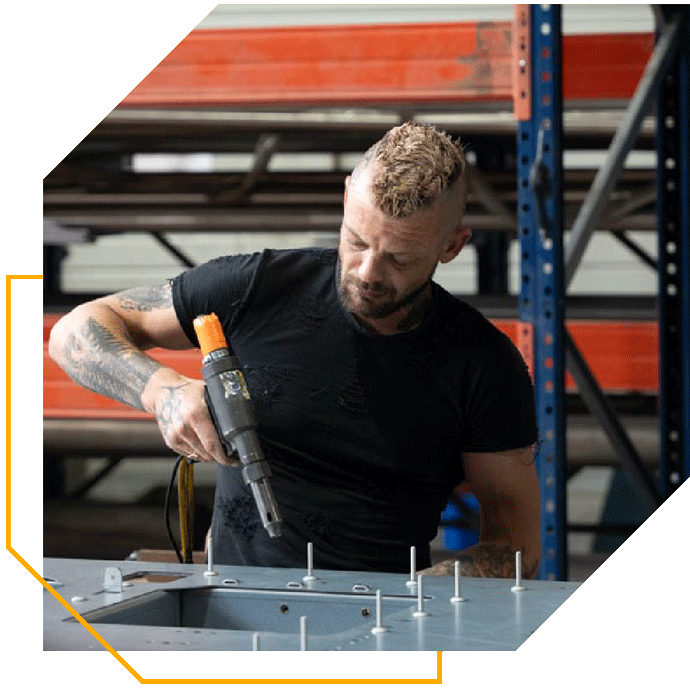

AssemblY

Assembly at Concept Métal effectively combines screwing, crimping and riveting techniques to guarantee strong, durable structures. Thanks to these methods, we ensure robust and precise connections, adapted to the specific requirements of each project. This combination of techniques enables us to optimize the strength and reliability of our welded assemblies.

SCREWING

Screwing involves joining parts together using screws to ensure strong, adjustable connections. This method allows easy disassembly while ensuring a durable connection, ideal for applications requiring subsequent modification or repair. At Concept Métal, screwing is integrated into our assembly processes to meet the specific needs of our customers.

CRIMPING

Crimping is an assembly technique in which one part is deformed to hold another in place, without the need for additional fasteners. This method ensures a strong, watertight connection, often used in industrial applications where strength is crucial. Concept Metal incorporates crimping into its assemblies to guarantee product reliability and durability.

RiveTING

Riveting involves the use of rivets to join parts together permanently and securely. This method is particularly effective for joining materials of different thicknesses or types, ensuring high resistance to mechanical stress. At Concept Métal, riveting is used for applications requiring strong, durable assemblies that meet industrial standards.

POWER CONNECTIONS

Concept Metal has been manufacturing power connections for the rail industry, including insulation, since 2015. Cutting is done by waterjet, laser or saw-cutting, followed by several stages of manufacturing and compliance testing. These connections will account for 17% of sales in 2024, and are managed by a team of five people.

MANUFACTURE OF POWER CONNECTIONS

Concept Métal se spécialise dans la production de connexions de puissance, essentielles pour le secteur ferroviaire. L’entreprise a intégré des techniques modernes d’isolation pour offrir des solutions complètes adaptées aux exigences du marché.

CUTTING METHODS

Power connections are cut according to part thickness and shape, using methods such as waterjet, laser or saw-cutting. These techniques optimize the precision and efficiency of the parts produced.

QUALITY CONTROL

Each connection undergoes a rigorous manufacturing process, including compliance tests such as visual inspection and dielectric testing, guaranteeing the safety and reliability of our products, which account for 17% of the company’s sales.

oUR PREVIOUS prOJECTS

cONCEPT METAL NEWS

Keep up to date with our latest news, innovations and projects, and find out how we continue to evolve to better serve our customers and the industrial sector.

🎉🔥 Fresh talent in the Concept Metal team! 🔥🎉

Nous sommes très heureux de vous présenter nos deux nouveaux visages arrivés dans la famille début Janvier.✨ Qui sont-ils ?👉 Benjamin Auguin, notre nouveau méthodiste ultra dynamique 💪👉 David Gerard, notre nouveau responsable...

Pink October

🎀 On Friday evening, our 6 volunteers joined 6,655 walkers and runners in the Tarb’elles, a charity race/walk dedicated to raising awareness for breast cancer screening. A beautiful gesture on their part! 🎀

cfao SOFTWARE

A question ?

a PROJECT ?

Get Your Personalized Quote Today!

Contact us now to receive a custom quote tailored to your needs. Our responsive and available team will support you throughout your project, offering personalized advice and solutions suited to your expectations. Don’t waste any more time, we are here for you!