Bending

The aim of bending is to give the desired shape to an originally flat sheet of metal, by exerting a permanent deformation. To achieve this, we use press brakes equipped with a punch and die to bend the sheet at precise angles. V-bending and air-bending are the most used methodes to meet our customers’ needs. These very common and widespread bending methods enable us to produce a wide variety of parts efficiently.

What you need to know: how the bend is obtained depends on the malleability of the metal used, the thickness and length of the sheet, and the direction of the bend.

what is folding in the air ?

department description

Industrial bending consists of deforming a metal sheet by applying forces to give it a specific angular shape, usually straight or curved. This process, carried out at Concept Metal using state-of-the-art press brakes, enables us to create parts with perfectly defined angles and bending radii.

Thanks to our modern equipment and rigorous work methods, we can master the production of complex shapes, while guaranteeing strict control of dimensional tolerances. Our expertise in bending enables us to offer a wide range of solutions for all types of industrial projects, from prototypes and small series to high-volume production.

Bending offers exceptional flexibility, both in terms of material types and dimensions. Whether for stainless steel, aluminum, steel, copper or other metal alloys, we have the tools and know-how to handle materials of varying thicknesses and characteristics.

our bending equipment

AMADA press brakes

Description of our four AMADA press brakes:

- 8-axis NC press brake lg 3000, capacity 100 Tons.

- NC press brake 8 axes lg 4000, capacity 170 Tons.

- 2 NC press brakes 8 axes lg 3000, capacity 100 Tons with automated tool magazine.

Advantages of bending at Concept Metal

Precision and efficiency

-

Press brakes for mass production of parts with precise angles.

-

Interface with CAD/CAM software, eliminating the need for manual programming by the operator.

-

Possibility of producing crocked parts.

-

Flexibility and speed of production thanks to automated press brakes.

-

Bending of parts up to 4 meters long.

-

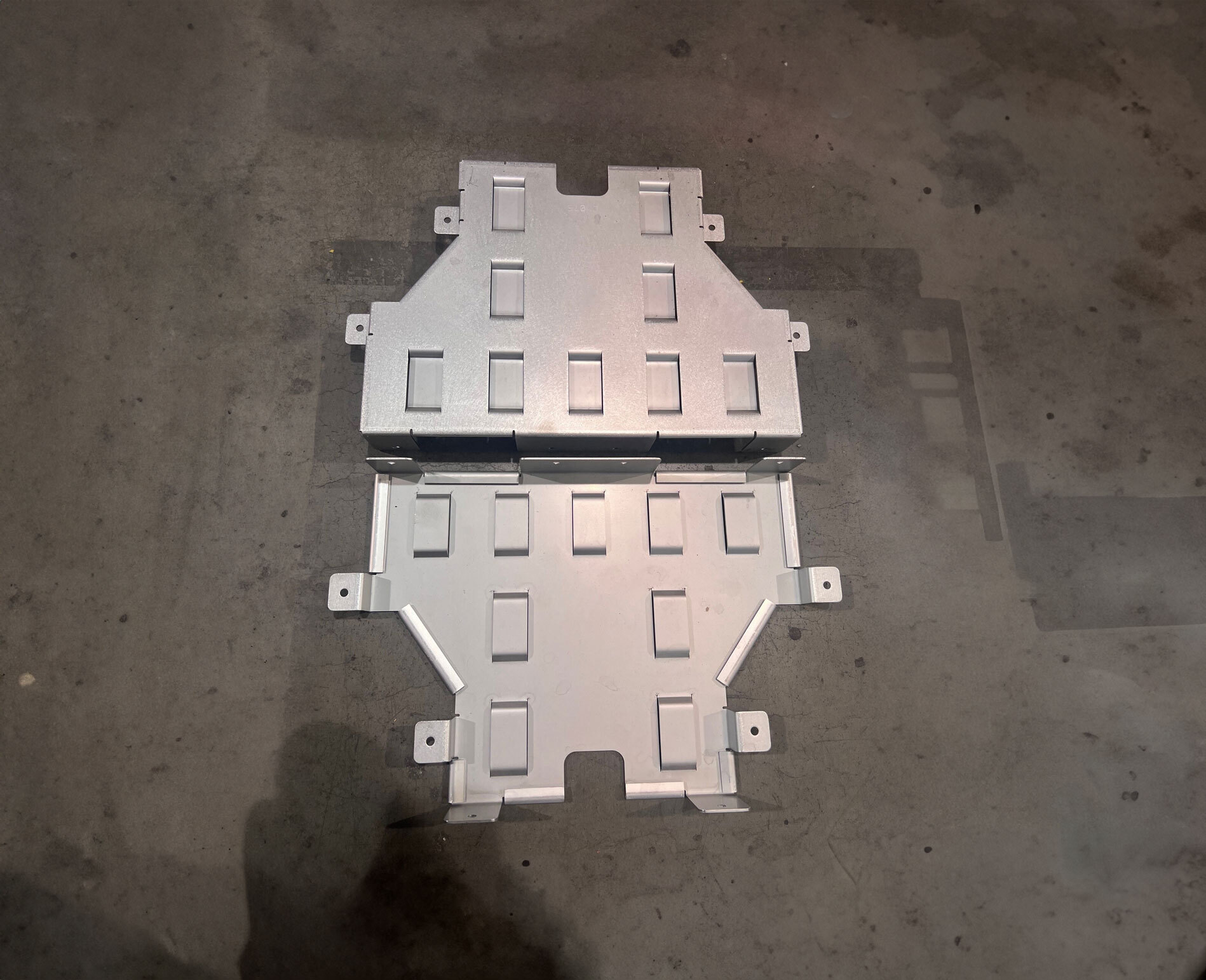

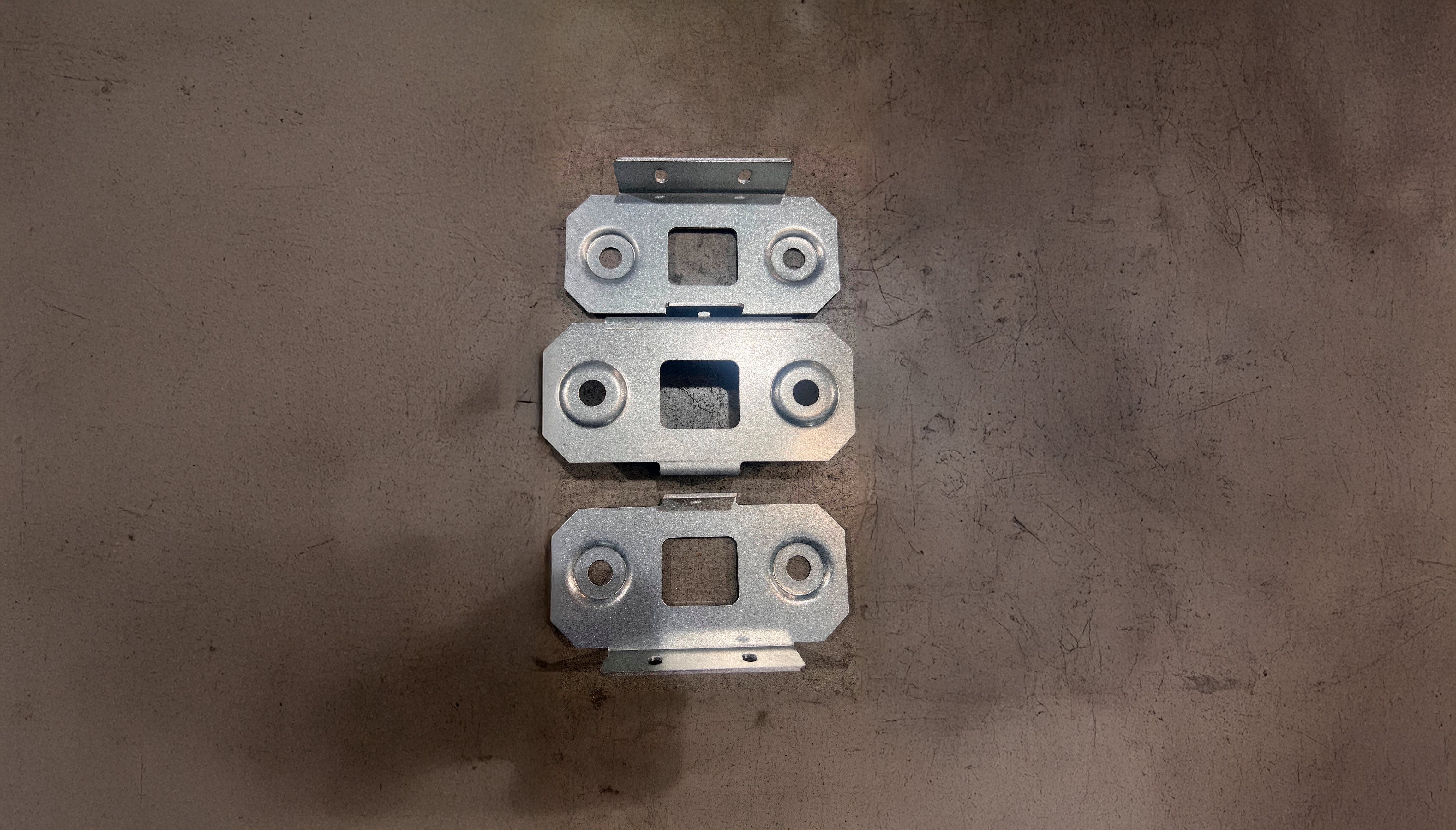

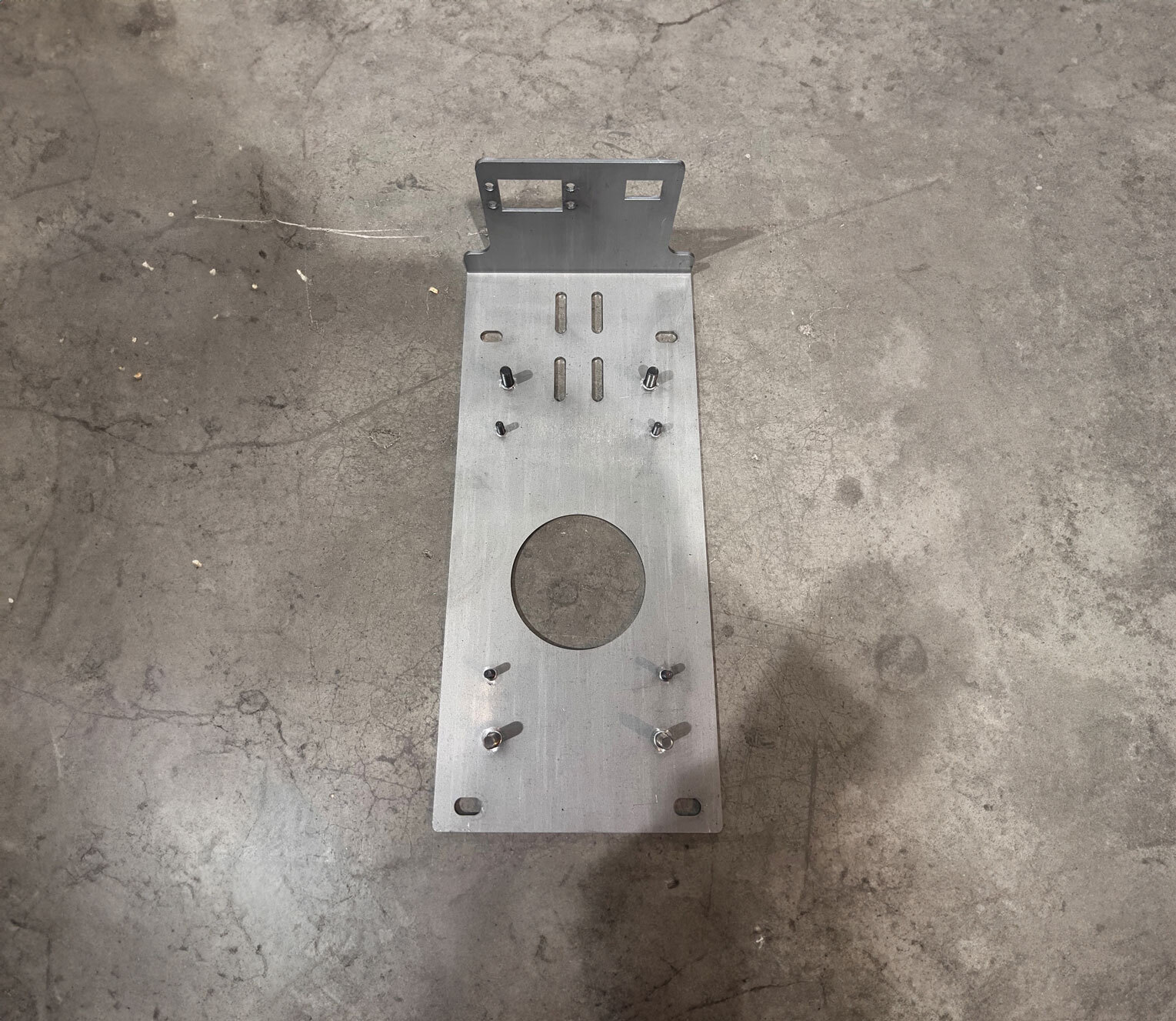

our achievements in bending

why choose us ?

commitment to quality

Industrial bending is at the heart of our expertise. Thanks to our cutting-edge technology, flexibility and commitment to quality, we can guarantee you precision-bent parts tailored to your specific needs.

We support you in your industrial projects, offering a fast, efficient and on-time service, while ensuring consistent quality.

a question ?

a project ?

Get Your Personalized Quote Today!

Contact us now to receive a custom quote perfectly tailored to your needs. Our responsive and available team supports you throughout your project, providing personalized advice and solutions adapted to your expectations. Don’t waste any more time—we’re here for you!