assembly

L’assemblage ou le montage intervient une fois que les pièces sont découpées et pliées. L’objectif est donc de lier plusieurs pièces entre elles afin d’obtenir un ensemble plus complexe. Pour cela, il existe plusieurs procédés et savoir-faire.

L’assemblage des pièces répond à des exigences techniques imposées par nos clients. Le choix du procédé de montage peut dépendre de plusieurs critères : l’esthétique, le coût, la durée de vie, l’encombrement. C’est donc une phase importante pour obtenir le produit fini. Un mauvais choix dans la technique ou le matériel utilisé peut avoir une incidence sur la qualité.

Chez Concept Métal, nous utilisons plusieurs procédés d’assemblage ce qui permet d’offrir différentes options à nos clients en fonction de leurs besoins. Nous maîtrisons le sertissage, le vissage, le rivetage et la soudure (et le brasage).

screwing

a few explanations …

whats is screwing?

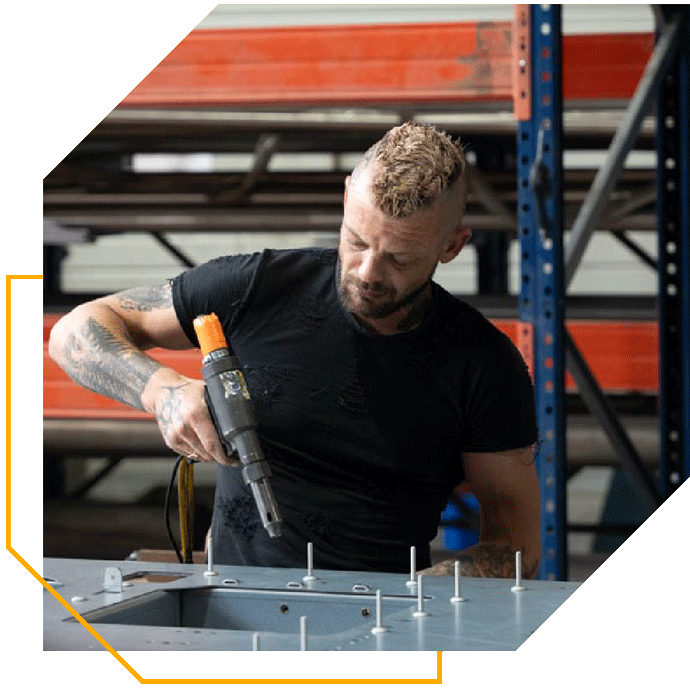

Screwing is the process of assembling two or more parts using a screw, a nut and a washer (or simply a screw with its thread in a part). It’s one of the most common fastening methods used in manufacturing and industrial assembly, thanks to its simplicity, reliability and ease of disassembly.

The choice of equipment depends on the requirements of the production process, such as speed, precision, type of material, and production volume.

We also carry out torque tightening with torque wrenches and electric screwdrivers.

Equipment used: Pneumatic and electric screwdrivers.

Riveting

what is riveting?

Riveting is a mechanical fastening process that permanently joins two or more parts together using rivets. We use this process to create strong, durable joints, particularly in areas where welding or other fastening methods are unsuitable.

Riveting involves inserting a rivet into pre-drilled holes in two or more parts to be joined. Once the rivet has been inserted, it is deformed using a riveting machine, thus mechanically holding the parts together. The rivet is then fixed into the part, creating a very strong bond.

We can use different types of rivets, each adapted to a particular use : blind rivets (pop rivets).

Equipment used: Pneumatic and electric riveting machines.

crimping

a few explanations …

what is crimping ?

At Concept Metal, crimping refers to the installation of crimping nuts. This process involves deforming the crimping nut to hold it in a pre-drilled hole, so that it can accept fasteners to create an assembly. Crimp nuts are particularly useful where access to the rear of the material is difficult, or can also be used on thin sheet metal that would not normally accommodate threads. Crimping ensures solid, durable, fast and precise assembly.

Equipment used: pneumatic and electric crimpers.

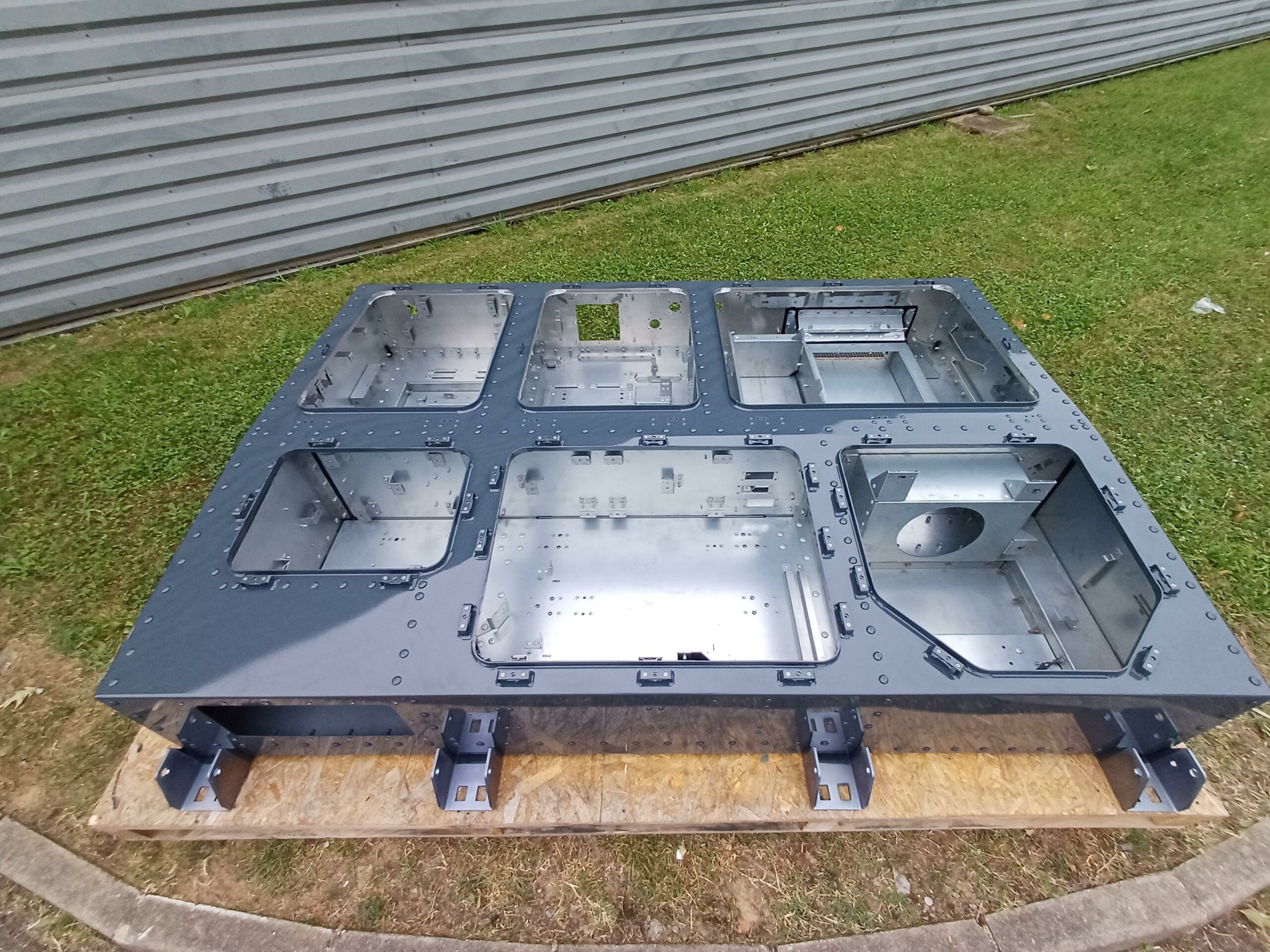

our achievements

in Assembly

Case of study

We regularly carry out assembly operations, ensuring the creation of coherent, solid metal structures. Our teams assemble a wide range of components, ensuring compliance with quality and safety standards to meet the specific requirements of our customers in sectors as diverse as railways, aeronautics and defense.

a question ?

a project ?

Get Your Personalized Quote Today!

Contact us now to receive a custom quote perfectly tailored to your needs. Our responsive and available team supports you throughout your project, providing personalized advice and solutions adapted to your expectations. Don’t waste any more time—we’re here for you!